At TechRock, our vision is to revolutionise in-situ stress estimation in the mining and energy sectors. We are at the forefront of innovation, developing cutting-edge technologies that redefine how in-situ stress is measured and managed. Our advanced solutions, including the iStress software, DCDA Laboratory technique, and DilaStress downhole tool, provide unparalleled efficiency, and reliability, setting a new benchmark for the industry.

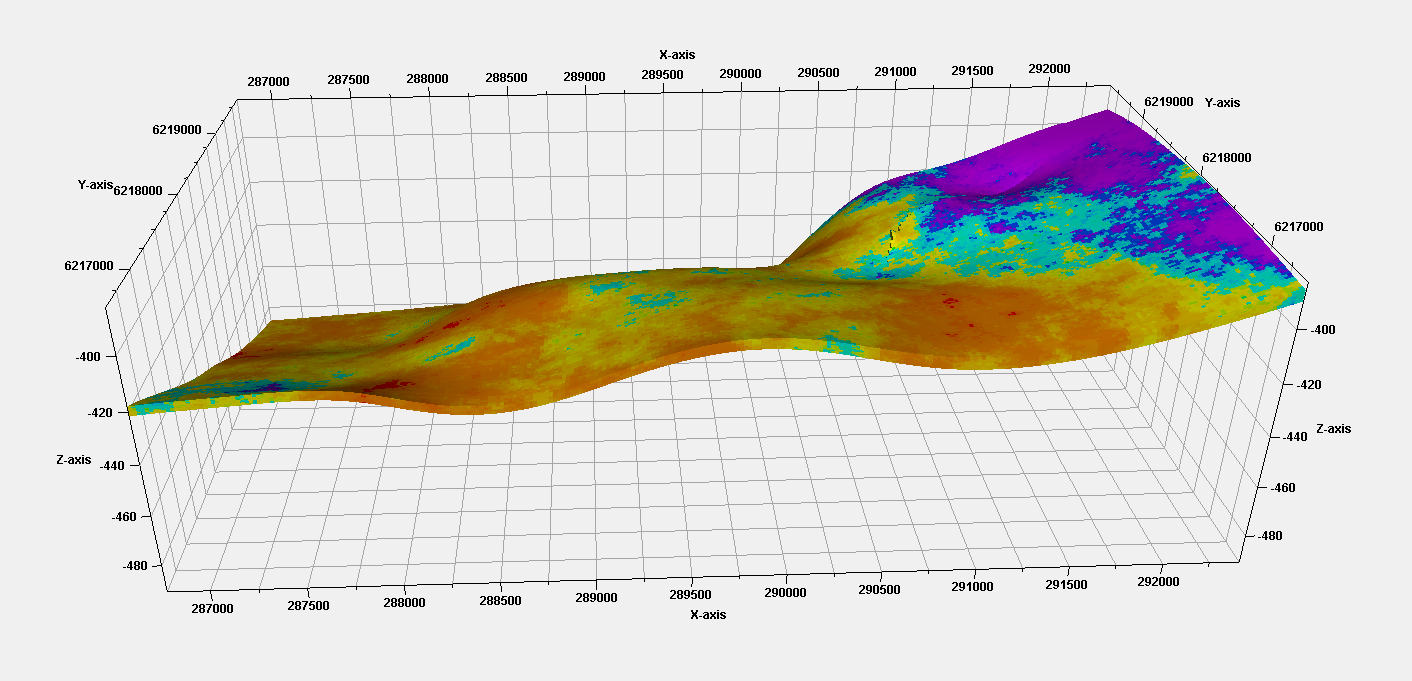

iStress is a cloud-based software that utilises ATV data combined with geotechnical properties to deliver reliable in-situ stress estimations. Powered by an innovative algorithm, iStress integrates borehole deformation analysis with borehole breakout analyses, providing a comprehensive and reliable assessment of in-situ stresses. Mining sites can either acquire iStress licenses with expert training provided by TerraStress Solutions or opt to have the analysis conducted by our experienced team as a tailored consulting service.

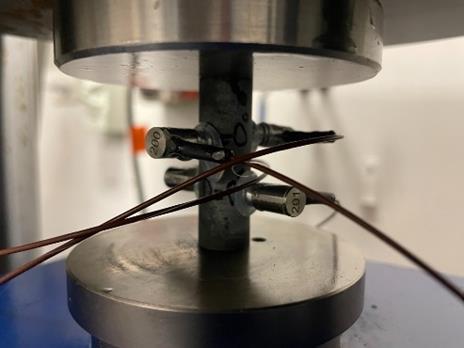

TechRock introduces the next generation of stress measurement combining the Diametral Core Deformation Analysis (DCDA) and ultrasonic mapping, a groundbreaking technique for 3D in-situ stress estimation from core samples. This advanced method delivers reliable in-situ stress orientation and magnitude, providing unprecedented insights into subsurface conditions and enhancing our capability to tackle complex geotechnical challenges with precision and confidence.

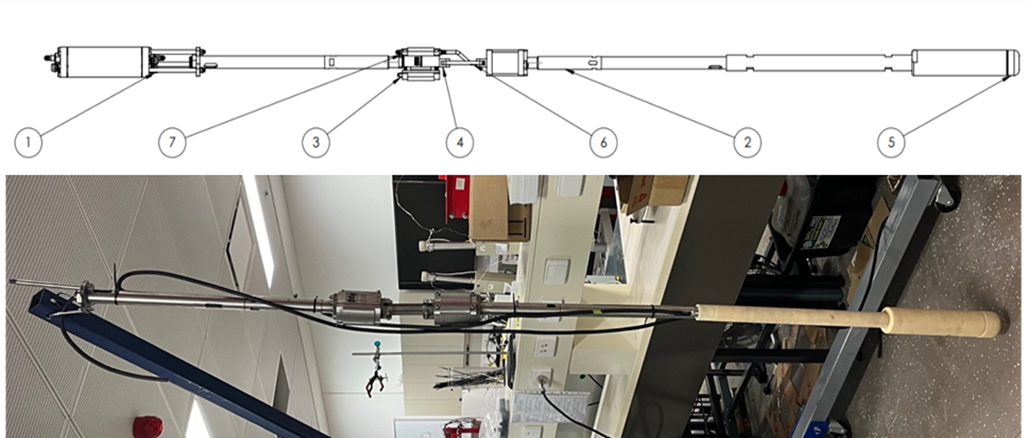

DilaStress represents the next generation of in-situ stress measurement tools, designed to replace conventional downhole methods that are costly, complex, and time-consuming. Leveraging an entirely new innovative concept to stress measurement, DilaStress simplifies field deployment, drastically reducing costs, operational complexities, and measurement time while enhancing reliability. This innovative tool sets a new standard for in-situ stress estimation, making it an indispensable asset for the mining and energy industries.

BLASÉ software uses the available downhole geophysical logs and converts them into in-situ stress profile across different formations interested the borehole. The measurements are readily calibrated with any available in-situ stress estimation in the borehole or nearby.

The AEA technique has been used for several decades to determine in-situ stress orientation and magnitude from core samples using the Kaiser effect. One of the key challenges in AEA stress analysis is the subjectivity in identifying the stress pickup point from the received acoustic signals. To address this, we have enhanced the analysis by applying advanced signal processing techniques, aiming to make the stress detection process more objective and reliable.